INTRODUCTION

First Testing Lab

First Testing Laboratory (FTL) is a part of M/s Libermann International. It has been established by the company’s management to improve the quality of products through testing using International standard methods, national standard methods, and laboratory-developed methods. Currently, The FTL is housed on the premises of the company building and carries out testing activities relating to the company’s textile and leather/synthetic leather products to assuring their quality to meet the requirements of customers/buyers. The company certified its products according to Cat I, Cat II, and Cat III categories of CE marking for its gloves and workwear garments.

The company is committed to abiding by legal and regulatory requirements to enhance customer satisfaction through the effective application of an efficient Quality Management System (QMS) including an appropriate testing system in FTL Laboratory. For this purpose and international recognition, FTL is going to be accredited shortly by PNAC.

MECHANICAL TESTING (GLOVES)

Protective Gloves Against Mechanical Risks: (EN 388:2016)

PPE gloves are evaluated against abrasion, Blade cut, Tear and puncture resistance for their assessment of protective usage. Standard is used in unification with EN 420. A protective glove must achieve level 1 or higher to pass the standard. Materials dulling the blades are tested according to ISO 13997 TDM/ISO cut tester, and the gloves/arm protectors which are used for specific protection are tested according to impact resistance ISO 13994:2015.

MECHANICAL TESTING (GLOVES)

Protective Gloves Against Thermal Risks (Heat And/Or Fire) (EN 407:2004)

After flame time, afterglow time, and melting and dripping of gloves are tested after burning of gloves for 3 and 15 seconds in an FR apparatus. Resistance against Contact, convective and Radiant heat is checked along with Small and large splashes of molten metals (usually iron and copper molten metals are used).

MECHANICAL TESTING (GLOVES)

Protective Gloves-General Requirements & Test Methods: (EN 420:2003 +A1 2009)

Sizing and dexterity are two important features of glove ergonomic requirements along with Water Vapor Permeability, Water vapor absorption, and water resistance. A glove must fulfill the sizing requirements of EN 420 and it should allow as much dexterity as possible given in its purpose of usage. Gloves’ finger dexterity is checked by picking 5 centerless round pins in 30 seconds. Higher the dexterity, the higher the performance of the glove.

MECHANICAL TESTING (GLOVES)

Protective Gloves Against Cold (EN 511:2006)

Thermal insulation properties of gloves are tested through convective and contact cold tests. The glove designed to protect against extreme cold (below -30 0C) is also tested in this procedure. If coated material is used in gloves design then its flexibility should also be confirmed through the “crack method”. Water penetration is an optional requirement of the standard.

An example is as:

MECHANICAL TESTING (GLOVES)

Electrostatic Properties (1149-1/ 1149-2 / 1149-3)

Electrostatic discharge (ESD) of fabric is reduced with increased washings and passage of wearing time during practical usage of PPE. Cloths or garments, Footwear, and gloves are included in this category. The PPE which bears this mark indicates product testing and certification for ESD.

MECHANICAL TESTING (GLOVES)

Protective Clothing/Gloves For Users Of Hand-Held Chainsaw (EN 381-4 And 7)

Usually, the dominant glove hand is checked at 450 and 900, and cut-through detection gives its final results in PPE gloves. Design assessment is carried out according to the glove’s minimum length and width along with the distal edge of the protective material. The standard mentions 5 classes of gloves according to glove protection, and the class is defined according to the speed of the chainsaw cut through.

- Class 0: 16m/s

Class 1: 20m/s

Class 2: 24m/s

Class 3: 28m/s

Class 4: 32m/s

MECHANICAL TESTING (GARMENTS)

Protective Clothing – General Requirements (EN ISO 13688)

This standard covers different parameters of clothing like Chromium VI with aging, pH value of leather and textile, design assessment, ergonomic requirements, washing, and dry cleaning according to UIS, Dimensional changes due to cleaning, check of size designation and marking, etc.

MECHANICAL TESTING (GARMENTS)

High Visibility Clothing (EN 20471:2013)

Usually, the dominant glove hand is checked at 450 and 900, and cut-through detection gives its final results in PPE gloves. Design assessment is carried out according to the glove’s minimum length and width along with the distal edge of the protective material. The standard mentions 5 classes of gloves according to glove protection, and the class is defined according to the speed of the chainsaw cut through.

MECHANICAL TESTING (GARMENTS)

Railway Group Standard (RIS 3279-TOM)

Fluorescent materials and retroreflective materials should conform to this standard as the same as in EN 20471 for high visibility clothing. Following is the pictogram of RIS 3279-TOM:

MECHANICAL TESTING (GARMENTS)

Protective Clothing For Use In Welding And Allied Processes (ISO 11611)

Many garments and apparel should withstand severe conditions of heat and flame during welding or related works. Gloves meet this requirement bears the following pictograms:

MECHANICAL TESTING (GARMENTS)

Protective Clothing For Use In Welding And Allied Processes (ISO 11612)

Many garments and apparel should withstand severe conditions of heat and flame during welding or related works. Gloves meet this requirement bears the following pictograms:

MECHANICAL TESTING (GARMENTS)

Protective Clothing− Protection Against Rain (EN 343 2003)

Porosity and water proof-ness of clothing are major contributors to a garment’s comfort. The majority of waterproof garments usually are not vapored permeable, a major drawback of a garment. To overcome this problem such materials are designed which are water resistant and vapor permeable at the same time. These properties are tested in this standard in which Water vapor resistance (or Ret value) is given according to a class of fabric or garment.

MECHANICAL TESTING (GARMENTS)

Proposition 65 (Prop 65)

Prop 65 is an American Legislation of banned chemicals and this is a growing list comprising 900 banned chemicals. Companies have 12 months to comply with this requirement if a chemical is detected in a product, and in this case, a clear warning is placed on the product or its packaging.

FIELD TESTING (GARMENTS)

Due to increased awareness among the masses now the consumer is focused on finding garments or apparel with the best balance of protection, comfort, and price. Now the workwear garment industry is more quality conscious than ever. In the garment industry, there are several different ways to structure field testing. The procedure is that a busy company is selected to whom the product is provided sufficiently. After a certain time, the product is evaluated ergonomically in its day-to-day activities. Sometimes field measurements are carried out using different techniques like tape, rulers, photography, etc. After completion of FT, feedback is taken from the personnel involved in the relevant work or a task, and a statistical summary report is prepared for current and future references. Product risk assessment is also part of this testing program.

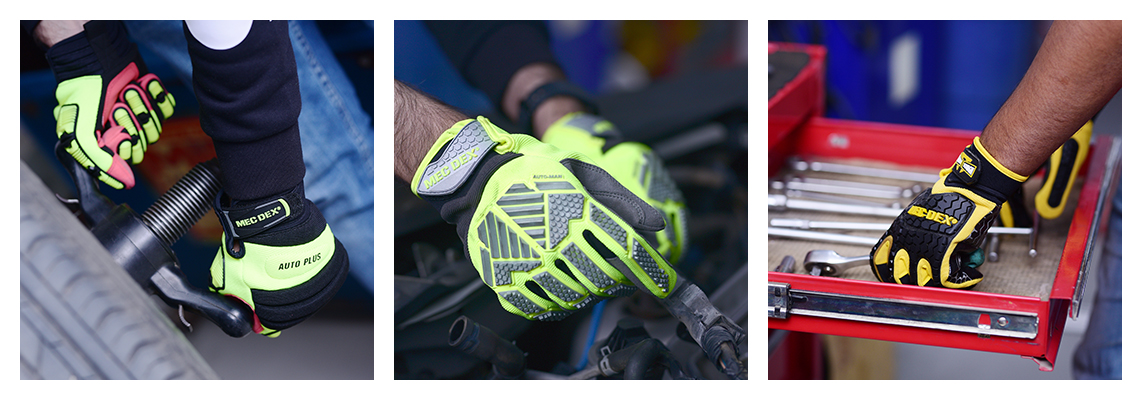

FIELD TESTING (GLOVES)

This is the policy of the company that before putting into the market gloves are tested in the in-house lab followed by field testing in which its initial picture of test validity and reliability is evaluated ergonomically. In this case first step is in-house lab testing and all the international and national standards are followed to meet the product specifications. Field testing is carried out according to the end use of the products, e.g., OF gloves series are tested in the petroleum field to evaluate the issues during its practical usage in the Petro industry. Chainsaw gloves are evaluated at saw machines and in-house blade cut machines at the same time. Many welding gloves can be evaluated in the TIG welding section and gas welding plants. Motorbike gloves can be tested ergonomically by a professional rider, like a courier rider or a recovery officer. In the same way, driving gloves are evaluated wearing by a professional driver of heavy or light vehicles.

COLORFASTNESS TESTING

Color Fastness To Perspiration (Acid And Alkaline) (ISO 105 E04/ISO 11641)

A fabric specimen is soaked in artificial perspiration solution (Acid or alkaline) and a piece of adjacent fabric also soaked in artificial perspiration solution, is laid against each side to be tested. The composite specimen is left under pressure in the oven for the specified period in a suitable apparatus. The fabric specimen and adjacent fabric are dried out and the change in color of the specimen and staining of adjacent fabric is assessed using grey scales.

COLORFASTNESS TESTING

Color Fastness To Rubbing (ISO 105X12)

Specimens of the textile are rubbed with a dry rubbing cloth and with a wet rubbing cloth, both in length and width directions. The machine provides two combinations of testing conditions through two alternative sizes of rubbing finger: one for pile fabrics; one for solid or large print fabrics. Staining is evaluated in the color assessment cabinet in white light. The color change is not evaluated in this method.

COLORFASTNESS TESTING

Color Fastness To Washing (ISO 15797/ISO 6330)

The washing test is carried out in Launderometer by attaching adjacent multifiber and washings at different temperatures are carried out in a controlled stainless-steel container. To increase mechanical action on samples steel balls are recommended and inserted in the method. Solid balls are inserted to boost mechanical action.

COLORFASTNESS TESTING

Color Fastness To Water (ISO 105 E01/ISO 11642)

A fabric specimen is soaked in demineralized water and a piece of adjacent fabric also soaked in demineralized water, is laid against each side to be tested. The composite specimen is left under pressure in the oven for a specified period. The fabric specimen and adjacent fabric are dried out and the change in color of the specimen and staining of adjacent fabric are assessed using grey scales. In the case of leather, it may be tested finish intact or with the finish broken. The test is performed on a Perspirometer of defined shape and dimensions.

PRODUCT CERTIFICATION

CE Marking & Oeko-Tex

No company can put their product into the EU market unless it is certified in the zone. Before undertaking CE marking risk assessment of PPE is carried out and all the ergonomic requirements are fulfilled. In this regard, the FTL lab is closely working with International Notified Bodies/Conformity Assessment Bodies (CABs) like BV Germany, BTTG UK, SATRA UK, Centexbel Belgium, Intertek, and CTC. Workwear Garments of the company are also OEKO-TEX 100 certified and are updated regularly on annual basis. In this regard, the company works with only OEKO-TEX-certified vendors in the region.

CHEMICAL TESTING LAB

The chemical testing lab of the company has much modern equipment like a spectrophotometer, state-of-the-art aging oven of Memmert Germany, shaking machine, pH meters, and laboratory-grade chemicals of Merck to perform chromium VI, Formaldehyde, and pH value. A chemical testing lab has been established in the tannery unit of Nizamsons (Pvt.) Ltd. Solid content of Pigments and active ingredients of fat liquor is tested in this lab. The boiling test is carried out according to a lab-developed method. The purity of acids and reagents is randomly checked to ensure the quality and consistency of the final product.