ARC FLASH

What is an ARC Flash?

An ARC Flash (also called a flashover), is the light and heat produced as part of an ARC fault, a type of electrical explosion or discharge that results from a low-impedance connection through the air to the ground or another voltage phase in an electrical system.

What causes ARC Flash?

Worker move near to contact energized conductors causing a spark that breaks down air insulation between conductors, and failure of equipment may create a spark that causes an arc flash between energized conductors.

Risk of ARC Flash?

ARC Flash can occur without warning and result in serious injury. Burns are one of the most common risks of these sudden electrical events and can lead to permanent disability in some cases. While the risk of ARC Flash has always been present. It is a growing hazard within many industries therefore we wanted to create a range of hand protection gloves that would provide protection against the risk of ARC Flash.

How is ARC Flash heat energy measured?

ARC Flash heat energy is measured in Joule/cm2 (J/cm2) or Calories/cm2 (cal/cm2).

What is Calorie?

A calorie is the energy required to raise one gram of water one degree Celsius at one atmosphere. The onset of second-degree burns may occur from 1.2 calories/cm2. One calorie/cm2 can be equal to holding your finger over the tip of a flame of a cigarette lighter for one second.

ARC Flash Gloves

ARC Flash testing rates gloves based on their resistance to sparks and flames (not thermal contact). Tough, long-lasting and designed to protect workers’ hands. these gloves protect hands from electrical arc flash in construction, automotive, assembly, maintenance, steel mills & TIG welding.

Most of the ARC Flash glove designs feature goatskin leather. Leather inherently performs well in arc testing due the nature of the hides themselves. However, not all leather is created equal.

ARC Flash Protection Equipment

With recent incresed awareness of the dangers of arc flash, there have been many companies that offer arc flash personal protective equipment (PPE). The materials are tested for their arc rating. The arc rating is the maximum incident energy resistance demonstrated by a material prior to breakopen (a hole in the material, as in case of EBT) or necessary to pass through (as in case of ATPV) and cause a 50% probability of second degree burns. ARC rating is normally expressed in cal/cm2 or a smaller unit Joule/cm2. Employer is not only responsible to provide suitable PPE to its employee but he/she is responsible to deliver the training of these to use them properly.

To better protect the hands from ARC Flash gloves will be either leather or rubber insulation gloves depending on the voltage. If rubber gloves are required, leather protectors or gloves must be worn over them. They need to be rated for the maximum voltage that a worker could be exposed to when working on the equipment. ARC rating come in 4 classes with 0 worst while 4 is best. It is to be noted here that PPE gloves which provide higher protection usually become bulkier and heavy and dexterity becomes a problem for higher voltages, Dexterity is an ability to pickup the objects by hand, so dexterity should be focused when manufacturing such type of gloves.

There are 2 methods of PPE selection:

SELECTION OF PPE BY TABLE METHOD OF NFPA 70E

Table method as it appears in the 2018 edition of NFPA 70E is going to be the best method to ensure personal safety when it is needed. There are many facilities or companies that will not be able or are unwilling to perform an incident energy analysis (also called calculation method), so the table method will be helpful for them to select a right PPE. Another aspect of the new table method that enhances worker safety is the fact that if any of the specified conditions for normal operating conditions are not met, arc-rated clothing and PPE are mandated. For the selection of right PPE table 130.7 in the NFPA 70E method is suitable.

SELECTION OF PPE BY Incident energy method of NFPA 70E

Incident Energy method (or calculation method is based on Cal/cm2 or Joule/cm2. This method is based on Hhazard Risk Category (HRC) ratings, and is performed after testing of the products from a renowned certified lab. ARC Flash risk assessment is performed at the PPE to ascertain its usage conditions. This option is mandatory if table method is not available. Very few labs in the world, especially in the north america, has the facility to perform this testing of incident energy.

ARC Test Standards – ASTM f2675 / F2675M-13

Incident Energy method (or calculation method is based on Cal/cm2 or Joule/cm2. This method is based on Hhazard Risk Category (HRC) ratings, and is performed after testing of the products from a renowned certified lab. ARC Flash risk assessment is performed at the PPE to ascertain its usage conditions. This option is mandatory if table method is not available. Very few labs in the world, especially in the north america, has the facility to perform this testing of incident energy.

ARC Flash testing

ARC Flash testing is relevant for any worker potentially exposed to an electic arc generation a heat flux of greater thatn 2 cal/cm2. Anyone with Exposure to electical hazard must have arc tested ppe available.

The incident energy which passes through the glove is measured and compared to the Stoll curve to determine a level of survivable burn. In any case in which the Stoll criteria has not been met but the fabric begins to crack open or display holes of a certain size, this point becomes the arc rating. The ATPV (arc thermal performance value) or EBT (breakopen threshold energy) are furnctional equivalents. The lowest of these two points designed as the “ARC Rating” of the gloves.

-

Heat Attenuation Factor (HAF):

This is aount of heat blocked by fabric, and applies to less than one second exposure time. In the event of prolonged heat exposure, the HAF would be much lower so a time factor should be mentioned when HAF is calculated. Higher the HAF value, better is the fabric against Heat Exposure.

-

Stoll Curve:

If we wish to determine the amount of heat passage quantitatively then Stoll curve can be helpful. Stoll curve identitfies a point where material

demands more protection is needed to avoid second degree burn. Stoll Curve works on two parameters of heat energy.

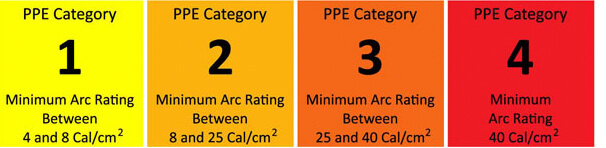

2015 PPE Levels

ARC Flash categories for the 2015 are based upon testing and analysis of the hazard and presented by PPE category number and incident energy as shown below.

Higher the value the best glove is. Higher values can absorb more ncident energy and are more suitable for energized equipment.

Knit fabric usually breakopen (EBT) before the burn point reaches so this phenomenon is called EBT, while in woven the case is opposite. Both ATPV and EBT are same parameters of 50% probability of second degree burn, while in reporting the lowest value is quoted as a material property. If the material has more thermal insulative value than arc tensile strength to heat, it breaks open first, as in the case of EBT (Knit fabric) while in the ATPV (woven fabrics) is the reverse case.

2015 PPE Levels

trangotek ARC Flash Gloves are certified and made of the highest quality material, While the protective gloves are designed to fully protec the fingers, hands and wrists from the heat of electrical discharge, they are engineered to help maintain finger dexterity. As a result, workers can still easily perform their required job duties while wearing the personal protection gloves.

trangotek are using highly engineered constructional material to protect your handn and ARC Flash resistance gloves. Thermal properties of gloves are influenced by materials (thermal resistance and conductivity), fabric construction (knit, woven and non-woven), fabric thickness (bulk density and layers) and coating of gloves. \

Try trangotek gloves of Arc Flash PPE to limit the risk of injury due to arc flash accidents. We stock a full range & sizes of gloves to help you select the most appropriate protection from the threat of arc flash. You can browse our range of arc flash gloves at www.trangotek.com